Why revamp or repower your PV assets?

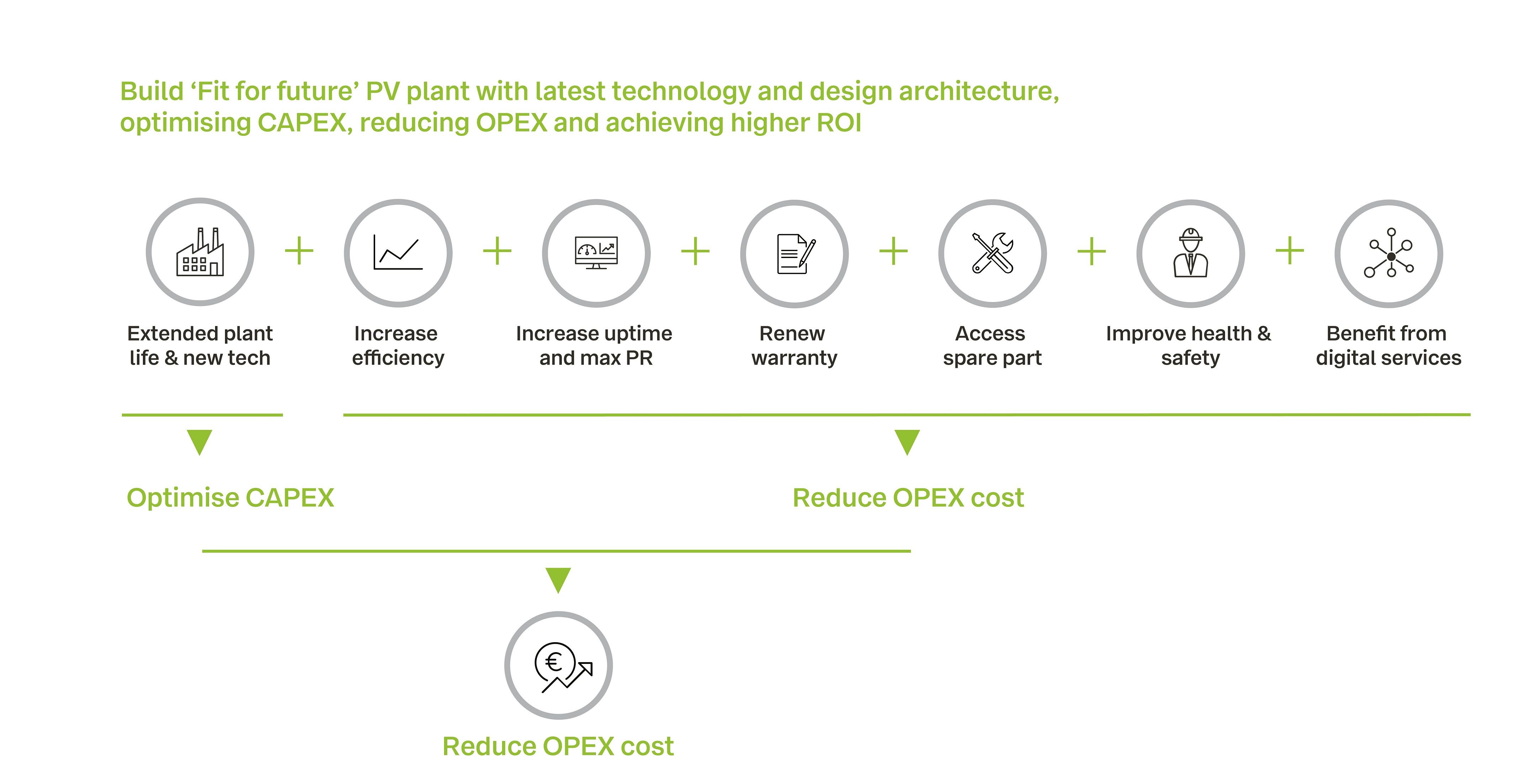

Repowering or revamping a solar park translates into a range of business benefits:

Maintaining performance: Replacing old, worn equipment cuts failure rates and business downtime. It can also increase the asset’s lifespan

“The output of solar panels can drop ~12.5% over 25 years, that drop could be even higher in hotter climates”

Sourcing critical components: Some legacy manufacturers have left the market, invalidating warranties and making important spare parts harder or more expensive to find

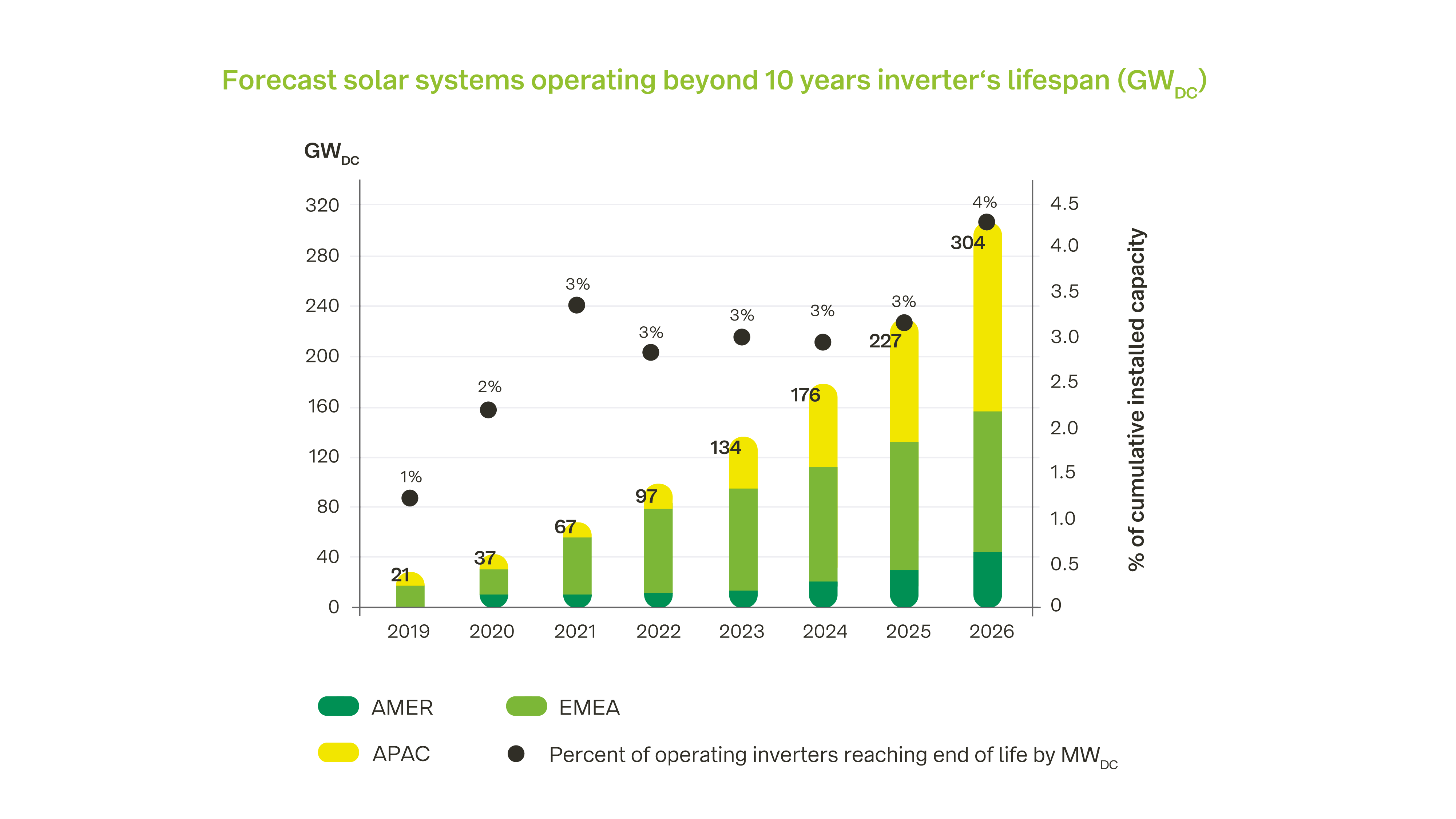

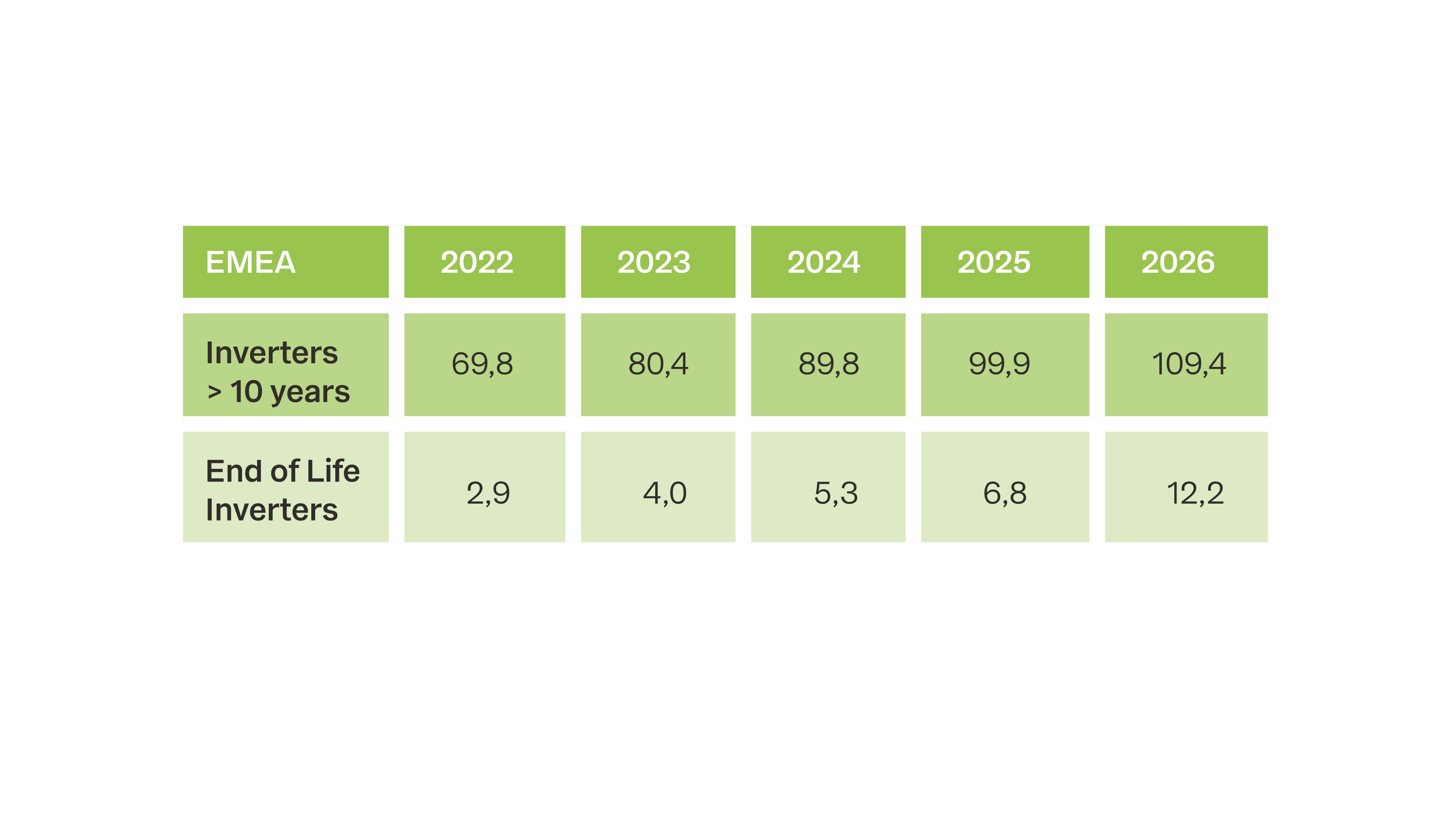

“Currently more than 69GWdc of solar PV inverters are over 10 years old in operation and 2.9GWdc at end of life expected”

Embracing new technology: Recent advancements make today’s PV tech far more efficient than legacy systems, often with a smaller physical footprint and renewed warranties

“PV modules are now hitting output of 650Wp and greater, boosting at least three times as much power output as 8 years ago. This means less than a third of area is now needed for same capacity generation”

Lowering costs: Today’s PV technology is significantly more cost-effective. Replacing legacy equipment represents long-term savings, as well as easier compliance with evolving regulations

“Solar PV costs fall 82% over the last decade and forecast to further reduce 59% by 2025”

Accessing new features: As well as extra capacity, new PV tech could add features like string-level monitoring. Huawei, for example, offers a smart IV curve function to reduce intervention costs and speed up analysis

Should you repower your solar park?

Any level of adjustments to a PV installation should improve performance for the asset manager. To calculate whether that improvement is worth the investment, compare two scenarios:

- The cost of extra maintenance on ageing systems and lost business across the plant’s remaining lifecycle

- Projected ROI from increasing performance and less maintenance over a potentially extended lifecycle

Repowering is most commonly discussed once there’s a notable drop in overall plant performance. By that point, inverters may be failing. Access to spare parts might be limited, since their manufacturers are no longer active in the market.

That means protracted periods of downtime – business suffers. Taking a proactive stance towards repowering can significantly increase profitability even before these problems start arising.

It’s also worth mentioning the potential to forge closer relationships with installers. Many might only sell to a customer once at any real scale, when the plant is first constructed. Afterwards, they’d only be called upon for replacement parts every once in a while.

Regular repowering gives installers more of a chance to familiarise themselves with your asset. Efficiencies increase, and they’re able to offer better professional advice about adding complementary systems like battery storage.